Mayte Cardenas. Photo by Tira Howard Photography

By: Sarah Boisvert

A Jewelry Designer from Rural Mexico

Who Embraced New Collar Technologies

I worked in a Chinese restaurant for eight years. There I discovered that the word for “failure” doesn’t exist in Chinese. In doing anything, you learn what doesn't work and if you choose to stop, that is your decision. My point of view is that I will keep trying until I succeed.

UNUM: Have you designed jewelry all your life?

MC: Oh no! I grew up in a little town in Mexico and my parents divorced when I was 8 years old. We moved to the city for my mother to find work. My grandparents and the Catholic Church didn’t approve of divorce so it was very hard. My mother had to be very brave, as we all have to be brave.

How the world sees women has changed. I want to be seen as a person, not just a mother or a daughter or wife.

I always tried to learn in different ways. When I was young, I liked crafts, making decorations for family parties. I was an entrepreneur in Mexico, with a small retail business, reselling things others made. So I’ve always had an entrepreneurial spirit.

Photo By Tira Howard Photography

UNUM: How did you manage the transition to the U.S.?

MC: When I was 26, we moved to the U.S. where I worked at jobs with lots of customer interaction. It was hard. The language was difficult for me and I felt isolated despite my family relationships.

I realized that for opportunities that interested me, English was required.

Communication skills were essential. If I wanted to go to school, it required English. How could I go for a job interview if I didn’t speak English?

So I enrolled in the Basic English offered at the public school. They encouraged me to take advanced English at Santa Fe Community College and luckily I had a tutor from school, so I was able to learn words needed for my job. I was working as a cashier at a gas station and there were so many items at the convenience store whose names I didn’t know. Often someone came in asking for directions and I wanted to help them.

UNUM: So, Mayte, how did you get involved in designing jewelry?

MC: I met my husband, Jacinto, and we wanted do have a business together.

Jacinto’s experience in Mexico involved jewelry, since he had worked for a casting company. My own grandfather was a metalsmith, so I understood the metal-working industry. It seemed logical to take jewelry classes, so I returned to SFCC to get started.

Design is my biggest passion. Taking something from nothing to a product is a big accomplishment for me. Regardless of the materials and the difficulties, seeing a finished piece gives me great satisfaction. I have a love for the stones. People’s reactions make the work very fulfilling.

I started making jewelry from hand designs.

UNUM: How did you come to open the business?

MC: Jacinto lost his job in the big recession and had a heart attack because of the stress. We had savings, so I felt this was the best time to start the jewelry business we had been talking about. The flexibility of schedule while you enjoy what you do would let me have more time for my family.

We purchased the most essential tools, and used ingenuity to compensate for what we didn’t have. I pushed Jacinto for 15 days to do the first casting and as I hoped, it turned out beautifully. The system worked.

In order to keep the equipment busy, we started Superior Casting Services at the Santa Fe Business Incubator. We provided casting for other companies while developing our jewelry business.

UNUM: Why did you turn to 3D designs?

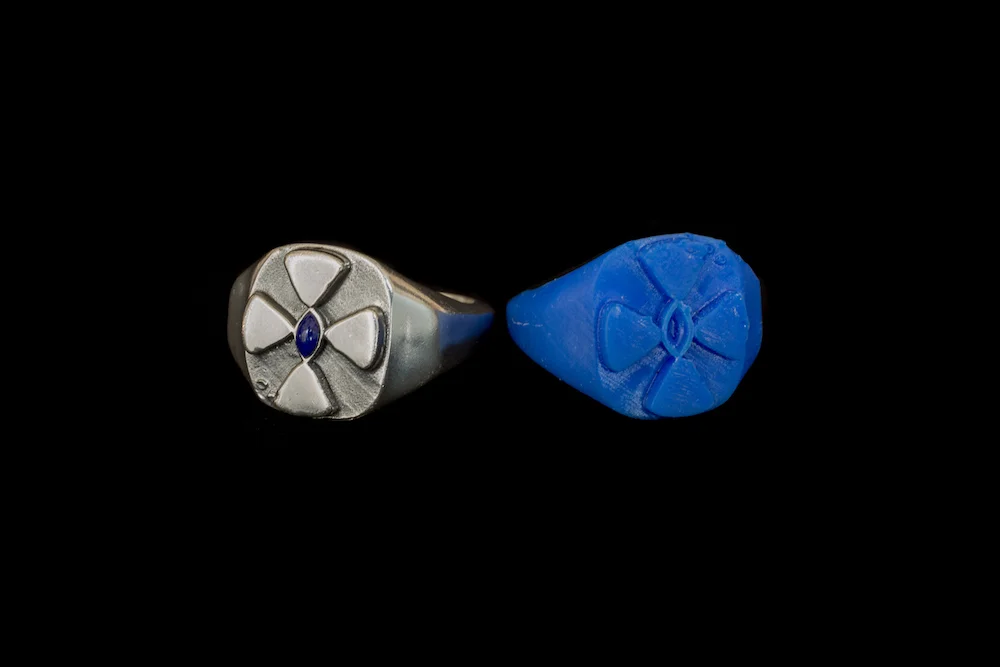

MC: I had ideas for designs that were too difficult to make by hand, but I would not be deterred. I researched on the internet and found this new technology, 3D printing, but it required Computer Aided Design [CAD]. So I took the software class, 3Design V9 Shaper, to get started. It was very difficult — the course was in English and went very fast, so I got them to let me take the class again. The most important aspect was that I practiced every day to master the program. In 1.5 to two years, I felt good about my skill.

If I have a design and hand make it, it takes three to five days to perfect the design for one piece. This increases the cost and takes me away from the rest of the work. CAD allows me to complete the design in one day, and if it needs tweaking, it’s easy and fast to change in CAD.

I bought a low-end 3D printer and tried hard to make it work, but it was not cost-effective. I could not find anyone anywhere with good enough printer quality and experience with the machines. But again, SFCC came to the rescue: We found a Fab Lab Hub that now 3D prints my designs on a high-resolution printer. 3D printing lets me make finer pieces, faster.

Getting into 3D expands our casting business, as we can work with other jewelers and we understand the process of working with their designs.

Customers can be anywhere … we have the internet; they find you online, pay via PayPal.

3D printing has changed my life!

Photo by Tira Howard Photography

Photo by Tira Howard Photography